Here is the roll of rugs fresh off the Weaver's Delight, and stretching down the upstairs hallway. I'm taking the photo from one bedroom, and Bob is in the one at the end of the hall. I haven't taken a measurement of them yet. They turned out better than I expected, and the selvedges are great.

The roll from the other end.

Close-up of the first rug.

Close-up of the second rug.

The short rug for our bathroom by the shower.

The last rug. Strips of four neutral colors, one with flowers and leaves that give the random splashes of color.

Sample using some of the left over weft, and the blue is blue jean strips. About 3/4" wide is just about right for the strips. The last little bit is just using some of my hem yarns. Just a sample, or maybe I will use it on the table for setting hot dishes on it.

The excitement of getting them off the loom has worn me out! Bed, here I come.

Monday, September 10, 2012

Sunday, September 9, 2012

Lessons Learned on the Weaver's Delight

The last rug on the first warp was finished tonight on the Weaver's Delight. I really do love the chicken tracks pattern. I'm hoping others do also, since I want to sell the ones that turn out well.

How satisfying to see a nice roll of rugs on the cloth beam. They will have to wait until tomorrow evening to be removed, since I still have a bit of warp left that I will make into a sample.

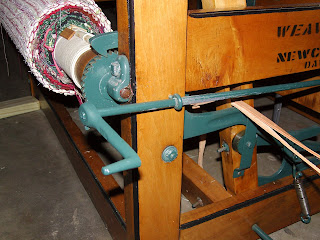

Along the way, while weaving this first warp, I learned some things about the loom. This was my first experience with sectional warping, and it is obvious that Bob and I have to be a little more careful with counting rotations, as evidenced by the photo. Oops! That little bit left to weave will be my sample, and then I am going to undo the edge sections and finish up the warp with a couple placemats on the narrower warp.

Also seen in the bottom edge of the photo are weights that I used on my last four edge threads on each side. I'm hoping with the weighted selvedges, that I won't have wavy edges.

The canisters took a little getting used to to load them. I didn't get a "pink pony" with the loom so I had to do it by hand. I found a pretty thick dowel in the workshop to compress the weft material into the tubes, but it seemed to stick to the insides of the tube, so I tore the cover off an old phone book, and that slippery, heavy paper made it much easier to get the tube loaded. As I filled it a bit, I pulled the paper out more, so I always had a deep tube. My tubes are still rusty, but not so bad on the inside, so no, my fabric did not pick up rust.

The yarn poking out of a couple of the tubes makes good hems on the rugs. It is about the weight of the Sugar and Cream type yarn used to knit dishcloths. I use two strands and get a hem like the white and rust sections with the closer chicken tracks. I do have an industrial sewing machine to sew the thick hems. I could do it on my regular sewing machine with some special techniques, because the yarn is soft, but I don't need to, since the heavy machine is designed for that type sewing. Chicken Tracks even makes a nice hem!

This machine travels! The 2x4s on the floor were braced against the front corners, but they only help a little bit, and then I have to tug at the loom and move it back. I actually think I need to brace it in two directions, since it tends to move forward and to the left. I will have to work on that when I find a more permanent location for the loom. Right now it is in the garage where my car will be this winter.

The tension adjustment on the brake band will determine how far forward the beater will come when beating the rug. Much further back from the front post than this amount will start causing problems with the shed changing mechanism and the fly shuttle mechanism.

I have found that this distance is about ideal, but not any closer.

Broken warp threads seemed to be inevitable, so I quickly learned to leave plenty of extra warp on the repair section. That way, I had enough to pull forward through the heddle and reed and could get the knots between rugs once I finished the rug I was on. Leave enough warp behind the loom to finish the current rug, and enough to weave the next rug. It will save headaches of having knots that you have to keep an eye on behind the heddles.

I like weaving rugs while standing. I think it is easier on my shoulders, and the leverage is great. I never missed the treadles even once!

I thought I learned to keep an eye on the nuts and bolts, to make sure they stayed tight, and then I looked down at the floor, and the nut and washer under the tension rod was on the floor. Before the next warp, I will have to go over the whole loom and tighten everything and oil all the moving metal parts.

Another bolt that I had to keep an eye on was the big bolt holding on the cams. With the loom warped, it isn't visible, so it's an easy one to forget about. It has to be pretty tight, or it will constantly come loose.

All in all, I think I had a pretty successful first warp. I'm anxious to start learning more with my next one.

How satisfying to see a nice roll of rugs on the cloth beam. They will have to wait until tomorrow evening to be removed, since I still have a bit of warp left that I will make into a sample.

Along the way, while weaving this first warp, I learned some things about the loom. This was my first experience with sectional warping, and it is obvious that Bob and I have to be a little more careful with counting rotations, as evidenced by the photo. Oops! That little bit left to weave will be my sample, and then I am going to undo the edge sections and finish up the warp with a couple placemats on the narrower warp.

Also seen in the bottom edge of the photo are weights that I used on my last four edge threads on each side. I'm hoping with the weighted selvedges, that I won't have wavy edges.

The canisters took a little getting used to to load them. I didn't get a "pink pony" with the loom so I had to do it by hand. I found a pretty thick dowel in the workshop to compress the weft material into the tubes, but it seemed to stick to the insides of the tube, so I tore the cover off an old phone book, and that slippery, heavy paper made it much easier to get the tube loaded. As I filled it a bit, I pulled the paper out more, so I always had a deep tube. My tubes are still rusty, but not so bad on the inside, so no, my fabric did not pick up rust.

The yarn poking out of a couple of the tubes makes good hems on the rugs. It is about the weight of the Sugar and Cream type yarn used to knit dishcloths. I use two strands and get a hem like the white and rust sections with the closer chicken tracks. I do have an industrial sewing machine to sew the thick hems. I could do it on my regular sewing machine with some special techniques, because the yarn is soft, but I don't need to, since the heavy machine is designed for that type sewing. Chicken Tracks even makes a nice hem!

This machine travels! The 2x4s on the floor were braced against the front corners, but they only help a little bit, and then I have to tug at the loom and move it back. I actually think I need to brace it in two directions, since it tends to move forward and to the left. I will have to work on that when I find a more permanent location for the loom. Right now it is in the garage where my car will be this winter.

The tension adjustment on the brake band will determine how far forward the beater will come when beating the rug. Much further back from the front post than this amount will start causing problems with the shed changing mechanism and the fly shuttle mechanism.

I have found that this distance is about ideal, but not any closer.

Broken warp threads seemed to be inevitable, so I quickly learned to leave plenty of extra warp on the repair section. That way, I had enough to pull forward through the heddle and reed and could get the knots between rugs once I finished the rug I was on. Leave enough warp behind the loom to finish the current rug, and enough to weave the next rug. It will save headaches of having knots that you have to keep an eye on behind the heddles.

I like weaving rugs while standing. I think it is easier on my shoulders, and the leverage is great. I never missed the treadles even once!

I thought I learned to keep an eye on the nuts and bolts, to make sure they stayed tight, and then I looked down at the floor, and the nut and washer under the tension rod was on the floor. Before the next warp, I will have to go over the whole loom and tighten everything and oil all the moving metal parts.

Another bolt that I had to keep an eye on was the big bolt holding on the cams. With the loom warped, it isn't visible, so it's an easy one to forget about. It has to be pretty tight, or it will constantly come loose.

All in all, I think I had a pretty successful first warp. I'm anxious to start learning more with my next one.

Sunday, September 2, 2012

More Rugs

I have mixed feelings about weaving rugs. They weave fast if there isn't any variation to them, but I seem to be most attracted to the ones with stripes or more detail. There is such a lot of prep work that goes into a nice rug, that it usually takes longer than weaving it. Prepping is a lot of hard work, and some can be hard on the body. My hands are getting pretty sore, so I may soon have to take a break and get back to finer weaving with just yarn.

Before I got the Weaver's Delight up and running, I put a warp on Fanny. This one ended up with stripes in both directions. I was trying to use up some horrible old polyester doubleknit that I inherited. The warp will definitely wear out before the weft does! The majority of the rug is of a tan, gray, and white striped fabric cut about an inch wide. The narrower accent stripes are navy blue and burgundy strips. I cut them 1/2" wide and doubled them since these particular knits were kind of stiff. They packed in better that way. The red was twisted with the navy to give a little accent color. This rug is getting close to being finished. I haven't decided what will be next, but it may be one fabric, or one color with a twill variation. Denim could be a possibility if my hands and wrists hold up to the rotary cutting.

Before I got the Weaver's Delight up and running, I put a warp on Fanny. This one ended up with stripes in both directions. I was trying to use up some horrible old polyester doubleknit that I inherited. The warp will definitely wear out before the weft does! The majority of the rug is of a tan, gray, and white striped fabric cut about an inch wide. The narrower accent stripes are navy blue and burgundy strips. I cut them 1/2" wide and doubled them since these particular knits were kind of stiff. They packed in better that way. The red was twisted with the navy to give a little accent color. This rug is getting close to being finished. I haven't decided what will be next, but it may be one fabric, or one color with a twill variation. Denim could be a possibility if my hands and wrists hold up to the rotary cutting.I ran into a little difficulty today weaving this small rug. This is the third rug I have made on the Weaver's Delight, and the manual warned about checking the bolts for tightness. Things started to loosen up, and suddenly I couldn't make anything move. Being new to the loom, it took me a bit of looking before I figured the trouble was with the "A" part needing to be scooted a little to the left, toward the "B" part. I was able to complete the rug, but it started doing it again just as I was finishing the hem. I will get back to it tomorrow, in the daylight, when I can see what I'm doing.

Most of the rugs I am weaving are probably going to go up for sale. Our church regularly goes on a mission trip to Kentucky every year, and they need to raise the funds for any repair projects they sign up to do. Hopefully, I will have a stack of rugs before next years trip.

I actually wove this rug for us. We needed a small rug by the tub/shower that wouldn't cover the heat register on the floor. The light colored fabric is a recycled mattress ticking. I like how the striped fabric looks when woven. The rest of the fabrics are from my large stash, chosen to match the colors in the shower curtain. I'm determined to gradually whittle away at the many boxes of fabric upstairs in my studio.

The 8 1/2 yards of warp that I put on the WD is quickly coming to an end. I will probably get one or two more rugs from it, and then I will probably try the plain weave cams on the next warp.

Subscribe to:

Comments (Atom)