The article I was referring to in my previous post was from the March/April 1992 issue of Handwoven, page 57. It was an article written by Bob Owen, another Michigan weaver. I don't know if he is still around, since he was retired when the article was written. I learned a lot from the article about block weaves in relation to lace.

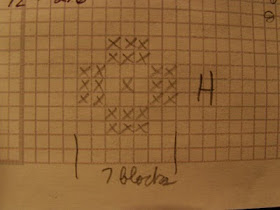

I drew up several designs, but chose to start with the one that was in the article. A block means that each x on the graph represents a group of threads. For this project, each block equals eight warp threads and eight weft threads. The squares around the design are also blocks that will be the Bronson Lace weave, and the design will be plain weave.

This particular design would require ten shafts without the pick-up method. This method only requires three shafts.

Here is my result of this design.

I wasn't real sure about the sett for this linen yarn. This sample is sett at 18 epi, and it appears a little loose. I decided to weave another design before cutting the samples off the loom and wet finishing them. I knew they would look completely different once they were washed, with the floating yarns scooting together.

So, here is my next design. It was a little harder to follow, with more skips and rows. I kept getting a little mixed up because I kept wanting to make the blank spaces be the plain weave instead of the x's.

This design turned out to be quite pretty.

While weaving this second motif, I snapped a few pictures of the pick-up process.

Raising shaft 3 raises groups of 3 warp threads. I had 13 groups in my sample.

A pick-up stick is used to pick up groups of 3 threads, according to the pattern. This is the first row of the pattern A.

With the pick-up stick in place, shaft 2 is raised.

Since the shed is small, I used a stick shuttle to weave with. This shows the pick-up stick against the reed and the stick shuttle weaving under the raised pattern threads and the threads on shaft 2.

The pick-up stick is then pulled out, and the pick is then beat into place.

Something else that I did with this pattern was to move some of my warp yarns that were supposed to be on shaft 1 onto shaft 4. It was suggested in the article to do that to space out the heddles. I moved every other one from the first shaft to the fourth shaft. The tie-up had to change also (every time shaft one is lifted, four also has to be lifted).

I love the look of Atwater-Bronson lace. This is the first sample after wet finishing. Linen shouldn't be dried in the dryer because it can ruin the sheen of the threads. I cold press mine with my marble rolling pin on my kitchen counter and just leave it there till it's dry.

My second sample, rolled and left to dry. I'm happy with how both turned out, but I will experiment a bit more with the remainder of the warp. I am going to resley the reed at 24 epi for the next samples to see which I like best.